Knitted sportswear fabric owes its moisture-wicking function to several processes and fabric technologies designed to manage moisture effectively. These processes and technologies work together to move moisture (sweat) away from the skin, distribute it across the fabric, and facilitate quick evaporation. Here are the key processes that contribute to moisture-wicking in sportswear fabric:

Wicking Materials: The choice of moisture-wicking materials is fundamental. Synthetic fibers such as polyester and polypropylene are commonly used because they do not absorb moisture like natural fibers. Instead, they allow moisture to pass through and spread across the fabric's surface.

Capillary Action: Moisture-wicking fabric relies on capillary action, which is the ability of a material to draw moisture along its fibers or surface. The small gaps or spaces between fibers in the fabric help create capillary channels that facilitate the movement of moisture.

Hydrophilic Treatment: Some sportswear fabrics undergo a hydrophilic treatment during manufacturing. This treatment modifies the fabric's surface to make it more water-attracting (hydrophilic), helping it pull moisture away from the skin.

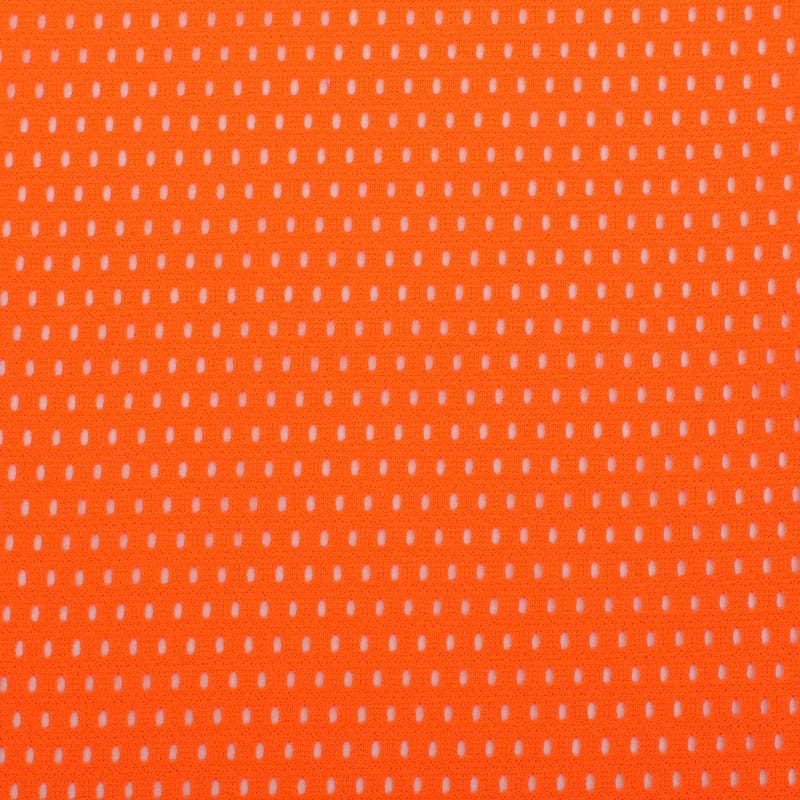

Construction and Weave: The construction and weave of the fabric play a crucial role in moisture management. Moisture-wicking fabrics are often designed with special knit or weave patterns that promote moisture transfer. These patterns create channels for moisture to move through the fabric.

Yarn Selection: The type of yarn used in the Knitted sportswear fabric can influence moisture-wicking. Multi-filament or multi-component yarns can enhance the fabric's moisture-wicking capabilities. These yarns have different properties that work together to move moisture efficiently.

Quick-Drying Properties: Moisture-wicking fabrics are engineered for quick drying. Once moisture is pulled away from the skin and spread across the fabric's surface, the large surface area allows for rapid evaporation, helping to keep the wearer dry.

Ventilation and Breathability: Some moisture-wicking sportswear incorporates ventilation features, such as mesh panels or perforations, to further enhance breathability and moisture dispersion.

Layering: Moisture-wicking is often incorporated into base layers or innermost layers of sportswear. These base layers transport moisture away from the skin to outer layers, where it can continue to evaporate.

Dyeing and Printing Techniques: Some dyeing and printing techniques involve applying moisture-wicking treatments directly to the fabric. These treatments can enhance the fabric's moisture management properties without compromising its appearance.

Quality Control: High-quality moisture-wicking sportswear undergoes rigorous testing and quality control to ensure that it effectively wicks moisture, maintains its performance over time, and resists saturation.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)