In the realm of textile manufacturing, the choice between circular knitted fabrics and woven fabrics often hinges on factors ranging from design versatility to production costs. Understanding how these two methods compare in terms of production expenses is crucial for industry professionals and consumers alike.

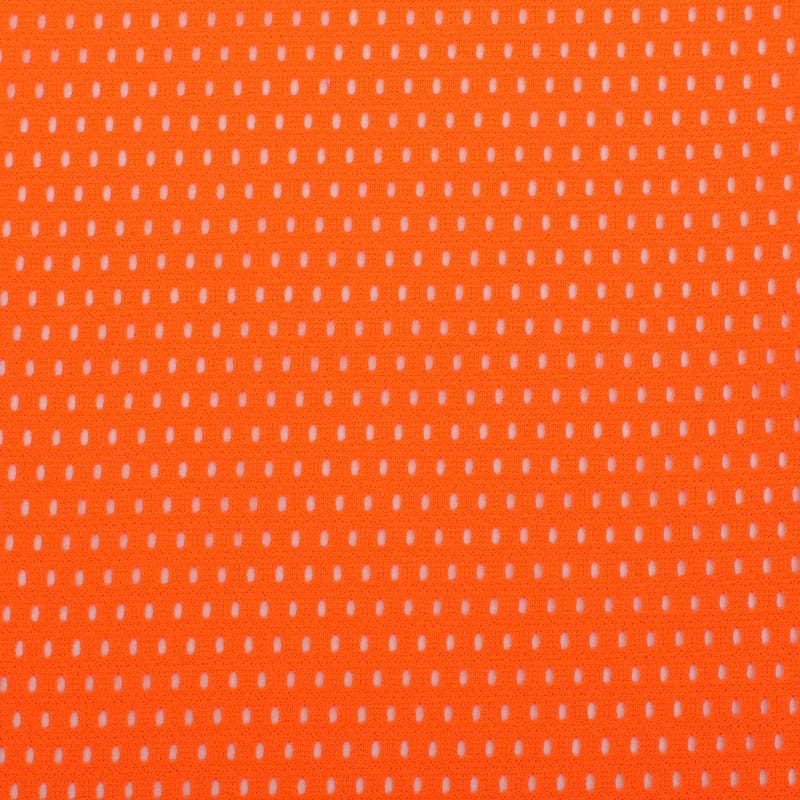

Circular knitted fabrics are renowned for their seamless construction, achieved through a continuous loop of yarns forming a tubular fabric. This method offers distinct advantages over weaving, particularly in terms of production speed and efficiency. Circular knitting machines can swiftly create fabrics with integrated designs, intricate patterns, and varied textures directly from the yarn feed. This efficiency reduces the need for additional processing steps and minimizes material waste, contributing to cost savings in both labor and material inputs.

In contrast, weaving involves interlacing two sets of yarns—warp and weft—at right angles to create a woven fabric. While weaving techniques have evolved to include advanced machinery like air jet and rapier looms, the process generally requires more complex setup and handling compared to circular knitting. Weaving machines are versatile in producing a wide range of fabrics, from sturdy denim to delicate silks, yet they typically involve slower production speeds and higher labor intensity for certain intricate designs.

The cost dynamics of circular knitted fabrics versus woven fabrics are influenced by several key factors. Circular knitting can be advantageous in applications where elasticity and stretch are critical, such as activewear and undergarments. The seamless nature of circular knitted fabrics enhances comfort and allows for greater freedom of movement, catering to modern preferences for functional yet stylish apparel. These fabrics are often favored for their ability to conform closely to the body, offering a tailored fit that enhances wearability and performance in various active pursuits.

Moreover, circular knitting technology has advanced significantly, enabling manufacturers to produce fabrics with diverse textures and functional properties directly from the machine. This capability not only streamlines production but also supports rapid prototyping and customization, which can be particularly beneficial in fast-paced fashion markets. The versatility of circular knitted fabrics extends beyond apparel to include applications in medical textiles, home furnishings, and technical textiles, further underscoring their value across different sectors of the industry.

In terms of cost, circular knitted fabrics may initially require higher-quality yarns designed for elasticity and durability, which can impact raw material expenses. However, the efficient production process and reduced labor requirements often offset these initial costs, making circular knitted fabrics competitive in the market. On the other hand, woven fabrics excel in applications where strength, structure, and intricate patterns are paramount, such as tailored suits and upholstery fabrics. The choice between circular knitting and weaving ultimately depends on the specific requirements of the end product, balancing factors of cost, performance, and design versatility.

In conclusion, while both circular knitted fabrics and woven fabrics offer distinct advantages and cater to different market demands, the cost of production remains a pivotal consideration. Circular knitting's efficiency in creating seamless, stretchable fabrics contributes to its appeal in industries requiring flexibility and comfort. As technology continues to evolve and consumer preferences evolve, understanding these cost dynamics will be essential for textile manufacturers seeking to innovate and remain competitive in a dynamic global marketplace.

English

English 中文简体

中文简体

.jpg?imageView2/2/format/jp2)